9 Oct 2018

Jamie Robertson discusses methods of monitoring this essential nutrient at farm level – and interpreting sample results – and offers guidance on how to sort issues.

Image © gozzoli / Adobe Stock.

Water is a vital ingredient to cattle production, equalled only by fresh air. It is a relatively low-cost input, which is a possible reason why such an important factor is undervalued at farm level.

Outside of a requirement to get annual measures of water quality for farms using non-mains water, most farms do not measure it. Does it matter?

The fundamental understanding of water requirements have been established in classical studies that related water intake to feed dry matter intake (DMI), feed dry matter, yield and performance, and environment temperatures. Extensive reviews are available (Defra, 2012).

Accessible practical guidance suitable for vets, many from North America, includes Alberta Agriculture and Forestry (2007), and Olkowski (2009).

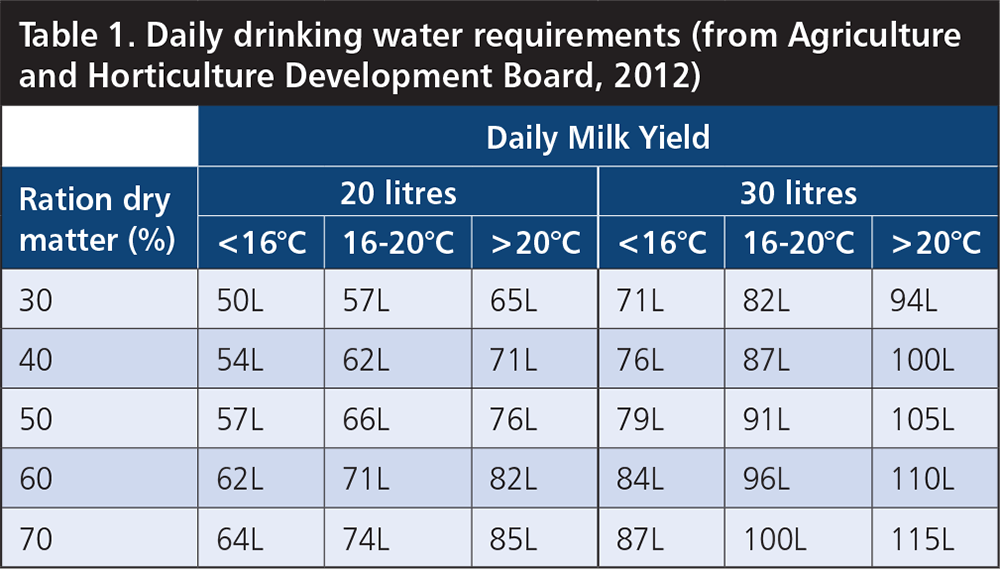

Tables 1 and 2 describe typical water requirements for dairy and beef cattle, respectively, and show the impact of different variables. Relatively minor changes can easily create demand changes greater than 10%, which may equate to an extra 1,000L per day for a group of 100 cattle.

The weather of summer 2018 will have tested water system capacities and served as a reminder of yet another factor that can give margin gains or losses.

Very little data exists on how much water cattle drink on commercial units, although many vets will have observed the occasional scene where it is obvious water volumes and available flow rates are inadequate.

The first level of monitoring involves a plastic jug and watch, to check flow rates at individual drinkers. Target any drinkers where stock appears to queue for water, with recommended minimum flow rates of 10L per minute, with maybe 20L per minute required in water troughs on the exit from the parlour.

Flow rate problems often require investment ranging from simple cleaning procedures, upgrading pipework or installing pumps.

Quantity of water available to cattle requires not only volumes, but also quality and access. Water quality at any one drinker is not guaranteed because a farm or building is on mains supply, and evidence shows water can become contaminated during storage and distribution between – and within – buildings (Lumb et al 2017).

Access can be an issue due to poor design of drinkers, pen layout, or both.

Poor quality can reduce voluntary water intakes, and reduced intakes will directly influence DMIs and, therefore, efficiency of production.

All non-mains water sources on livestock units should be tested annually for a range of chemical and microbiological factors. However, the quality of water at source is not necessarily the same as supplied to the cattle, and appraisal of water troughs around a farm is useful.

Testing can include physical appearance – such as odour, cloudiness or turbidity, or gross contamination (for example, sand or silt).

Thereafter, water needs to be sampled and sent for analysis. When submitting water samples, ask for an assessment of:

Sampling is an issue on farm because the number and frequency of samples are too quickly enumerated as a cost, with no regard to potential benefit. Correct sampling technique is essential and guidance is readily available (Agriculture and Horticulture Development Board, 2017). It will cost in the region of £200 to get the aforementioned factors analysed for a single source sample, plus a further four or five microbiological samples around the unit, to see how clean the water is at the point of delivery. It is money well spent, to know the most vital ingredient on the farm is clean.

Most commercial labs will supply aseptic containers and clear guidance on sampling technique. A badly taken sample could result in a costly outcome.

Interpretation of sample results is not necessarily straightforward because the guidance limit on any one variable is just that – guidance.

The frequency of a water-borne factor having an immediate and clear impact on animal health and productivity is very low, such as direct poisoning with a bacterial or fungal toxin. However, a data set of 140 UK livestock borehole water samples indicated 15% were above guidance levels for sulphates, and 6% for iron levels (Lumb et al, 2017).

Elevated sulphate concentrations can limit water intakes and cause diarrhoea, and elevated iron intakes can contribute to reduced copper availability and impact on late pregnancy cow performance.

Microbiological data is easier to understand because concentrations of viable bacteria, coliforms or E coli are either zero or very low, or significantly more than guidance levels, due to exponential growth. Examination of one of the largest UK data sets of water quality at pen level showed only 1.8% of samples were between 1,000 and 2,000 total viable bacteria (TVCs) per ml (Lumb et al, 2017).

The Red Tractor assurance standards for pig drinking water is fewer than 1,000 TVCs per millilitre (at 22°C) and fewer than 100 total coliforms per 100ml. The argument, not agreed by all parties, is it is not practical to suggest higher standards for coliform contamination in livestock water systems.

A number of livestock pathogens are extremely comfortable living in water – whether river systems, storage tanks or distribution pipework. E coli has variable stability in water (few days to a year), will still grow in sterile water and, when exposed to low temperatures/toxic metals (such as lead, copper, mercury and cadmium), can enter a dormant state. Cryptosporidium species survive for six months (at 5°C to 15°C), and Mycoplasma bovis is viable after 14 days (at 4°C). The potential to support cattle health by providing clean water is substantial.

Many commercial suppliers already exist that provide water cleaning systems to industry, with an established presence in the poultry sector and a growing understanding of the pig sector. Guidance is also freely available – Lumb et al (2017) being an example.

The target for practitioners is to find someone who is not merely a product salesman.

While cattle can be turned off water by taste and odour, and intakes will be reduced when water is cold (colder than 10°C; Lanham et al, 1986), problems can also exist with access.

The guidance for youngstock is for water to be available a few meters from automatic milk feeders, at a height the calves do not have to drop the neck too far to drink. If water and feed are both kept clean, helped by a degree of separation, calves eat more and increase growth rates.

Water should be placed in front of penned calves at least one hour after the milk feed, to prevent ruminal drinking. Bach (2018) has recommended calves should be drinking four litres of water per kilogram DMI before weaning.

Access to water for cattle in groups is a function of available trough length and location. Based on guidance that 10% of stock should be able to drink at one time, the minimum effective drinking perimeter of a trough would be similar to the feed barrier width for that number (10% of the group) and liveweight of cattle (Hulsen, 2012; RSPCA, 2018).

Water levels should be about 85cm above ground level – and 7cm to 8cm below the lip of the trough – to minimise fouling and excessive spillage. A rail set 20cm from the top of the trough, or a step up to the trough of 20cm height, is beneficial. Troughs should always be fitted with a means of stopping the water supply and emptying the trough completely.

The quantities of dirty water circulating on cattle units can be massive; on dairy units in the western parts of the UK, it may be described as a very expensive mistake.

Water may not be expensive, but dirty water carries hidden costs. Dirty water is a factor in poor biosecurity between groups, pens, buildings and farms, and adds to the time, energy and financial costs of waste disposal.

Clean rainwater – which, with investment, can be turned into a valuable resource at farm level – is too easily turned into uncontrolled dirty water at ground level, contributing to a diffuse pollution problem that is not sustainable. Only 7% of UK cattle units harvest rainwater (Defra, 2016), but a typical 200-cow dairy unit will have at least 5,000m2 of buildings and hardstanding, which easily converts clean rainwater into between 5,000 tonnes and 10,000 tonnes of dirty water per annum, dependent on climate and general awareness of the issue. Two hundred cows drinking 100 litres per day would only consume about 7,500 tonnes of water per year.

As a result, it is time to get a grip and help cattle farms be wise with water.