26 Mar 2024

While good-quality milk powders are important for calf development, the roles of quality colostrum, transition milk and dry feed should not be discounted, writes Selena Field.

Image © Sirichai / Adobe Stock

According to a live, online Q&A session, 85% of farmer participants feed a calf milk replacer on-farm, which was not a huge surprise.

But delving a bit deeper into what they prioritise revealed that 88% say protein is at the top of the list, with 27% going on to say crude protein. Then, when asked, 63% said they would look at the type of protein in the milk replacer.

Knowing what is best to feed the calf is one thing; understanding and interpreting the label on a bag of milk replacer is another thing entirely.

When it comes to legal requirements, manufacturers only need to declare the ingredients in descending order of inclusion, and many do not state if the product is on a fresh or dry weight basis.

It’s fair to say that due to rapid advances in nutrition over the past 50 years, chemical analysis of milk powder labels is no longer an indication of quality, but more a recording of how the feed was made. Is the way we label calf milk replacers fit for purpose these days? That’s a very good question.

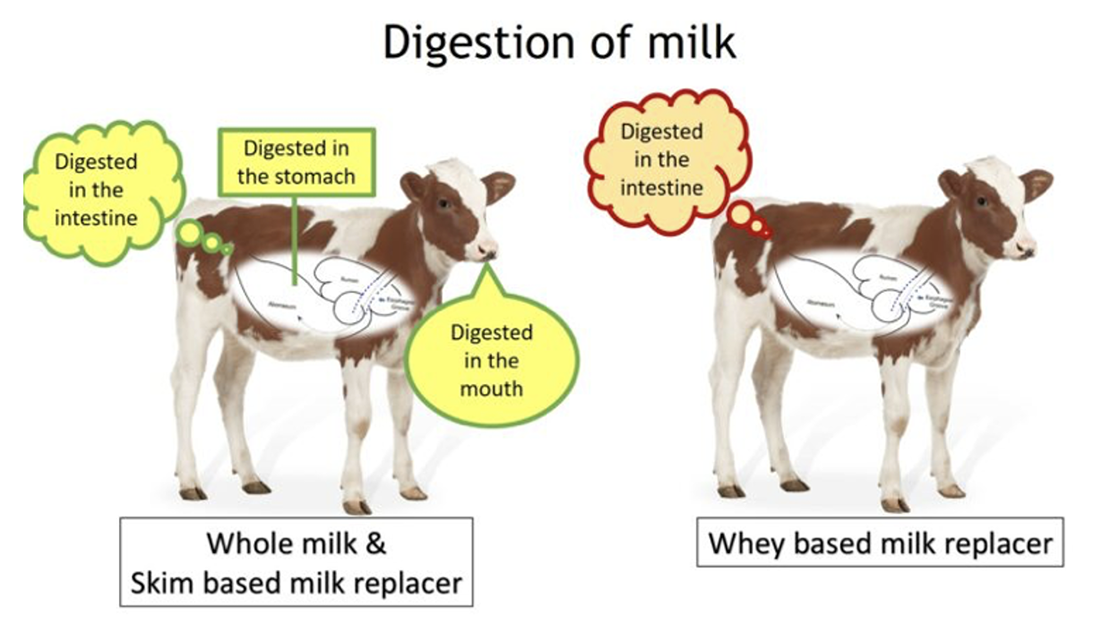

But to go back to basics momentarily, what do we know works well in terms of the digestion of milk? Ultimately, sticking fairly closely to cow’s milk, with an amino acid profile that meets the needs for maintenance and growth, is a good thing and makes for more effective digestion in the calf. The casein cow’s milk is digested the same way as the skim and buttermilk element of milk powder; the two work in tandem, with whey providing the initial hit of protein, followed by the skim and buttermilk element that facilitates slower release to the calf.

Protein – in other words, amino acids in milk replacers – and the profiles supplied are difficult to determine, as manufacturers are only legally required to list ingredients used, not quantity or quality. Therefore, used alone, crude protein has no correlation to calf health and performance. Heat treatment of milk and vegetable proteins during manufacture affects the digestibility of the amino acids available to the calf for growth and performance. A balanced quality amino acid profile, rather than crude protein of milk, is the more important consideration when determining digestibility to the calf and subsequent performance.

The four best milk proteins for correct amino acid profile for growth and development of baby calves are low heat skim milk protein, buttermilk milk protein, whey milk protein and whey protein concentrate. Others are available, but they tend to have gone through extra manufacturing processes and cannot always be used efficiently by the calf.

Calves will digest skim milk most efficiently due to it being the closest amino acid profile to cow’s milk. The next best option is buttermilk protein, due to the milk fat globule membrane clotting easily in the calf’s abomasum alongside its important antiviral properties. After buttermilk, whey milk protein would be the next best in terms of digestibility. This is due to whey milk protein being a by-product of the cheese-making industry and manufacturing processes potentially impacting its nutritional properties. With skim milk powder you get more bang for your buck, whereas whey has had all of its caseins and curds taken away for cheese-making, and that’s not something in the calf’s favour.

Whey milk protein is a good source of protein and sugar, but it can also contain derivatives of other milk proteins, which have been heavily manufactured, such as whey permeate or whey isolate. Again, while whey permeate and isolate are cheap, it is poorly digested by calves due to manufacturing processes.

Calves need the milk replacer to form a curd or a clot through coagulation during digestion, so enabling nutrients to be slowly released over time. The quality of the skim and buttermilk element determines how slowly or quickly this happens. Basically, you need the curd or clot to form rapidly before too much of the milk replacer passes through the abomasum.

For slow-release protein – from the skim – this also traps fat trace elements and vitamins for slow release, aiding their digestion, and this is what to look out for on the label and discuss in more detail with the supplier. Points to watch for include the quality of the skim, which will affect the speed of coagulation (clotting), and rapid formation of the clot, before too much passes through the stomach. Also, low heat milk proteins produced using lower drying temperatures are more costly to produce, but provide improved clotting and, so, better amino acid availability.

Crude protein in milk powders can also come from vegetable proteins, including hydrolysed wheat protein, pea flour and soya flour. Hydrolysed wheat protein is often considered as one of the better vegetable proteins to include, as others will contribute to the overall protein content, but can cause anti-nutritional effects.

The best advice for farmers is to use a milk powder with the highest milk protein they can afford – especially in the first four weeks of life. Post-28 days, when the calf is physiologically starting to produce starch digesting enzymes in abundance and is changing from a monogastric to a ruminant, is when vegetable proteins can be used.

When studying labels as part of the MSc, out of the 39 milk replacers analysed, a variation in protein levels from 19% to 28% was seen. In terms of what a calf can use, something in the middle of that figure would be the most commonly seen and the most optimal, as good quantities of low heat quality milk proteins are in there.

The temperature proteins are heated during processing will also affect quality. Milk proteins originally destined to be used in the food industry, such as in caramel chocolate or in baby food, will have been heated in high temperatures to remove bacteria. As a result, the proteins are denatured, which means they cannot clot in the calf’s stomach as required.

The rennin in the abomasum mixes with low heat skim or cow’s milk and it creates a curd that stays in the abomasum and slowly breaks down casein proteins before they are fed into the small intestine. If proteins have been subject to a medium or high heat, the curd will not form and the caseins will flow into the small intestine at a rapid rate, predisposing the calf to nutritional and infectious scour.

Farmers could be thinking that they are feeding good skim milk powder and cannot understand why they are having scour or looseness in calves. And, to add to the already-complicated picture, the temperature in which milk proteins have been heated to is not displayed on the label and can only be found by contacting the manufacturers directly.

High heat is good for food production because it heats all of the nasties out, but it means the casein fraction of the skim is damaged. This affects the curd as it does not coagulate, resulting in less natural microflora, and a harder protein for the calf to digest. Generally, low heated milk proteins are more expensive than medium or high heated, and it is worth a follow-up discussion with the manufacturer.

Fats and oils are referred to as one ingredient in milk powders and can come from a range of sources, including palm oil, coconut oil, linseed oil, rapeseed oil and sunflower oil. The most common sources of fat in milk powders are palm and coconut.

It is a good idea to select a milk replacer with a range of fats from multiple sources, to create a blend of short, medium, and long-chain fatty acids to support health and growth in the calf.

Buttermilk as an ingredient boasts 4% milk fat, with its milk fat the most digestible fat to the calf.

Critical to the calf being able to use fat is that it has been emulsified with the protein properly. If this doesn’t happen, poorly emulsified fat-filled whey can create fatty lumps during mixing that leaves a greasy residue and biofilms on feeding utensils.

Fat inclusion on the selection criteria list is integral to calf performance, but bear in mind that fat inclusions do not increase energy levels significantly and need to be considered with dry feed to encourage rumen development and not stunt it. Research has shown that, for every percentage increase in fat content, dry feed intake decreased by 11g per day1.

The recommended fat content is anything from 17% to 25% and the optimal amount of quality milk powder per head, per day would be between 750g to 900g, dependent on breed. Anything more will discourage concentrate feed consumption and subsequent rumen development2.

The consumption of fresh water, concentrate and forage causes bacterial fermentation in the rumen; produces volatile fatty acids, acetate, propionate and butyrate; and develops the papillae and musculature of the rumen wall, along with supplying energy to the animal.

The fibre levels displayed on a milk powder label are not always indicative of vegetable protein content. Manufacturers can declare zero if below 0.05% is in the formulation as the levels included in milk replacers are below test accuracy, therefore reading the ingredients list is recommended.

Ash levels are reflective of the mineral content within the milk powder – including calcium, phosphorus and sodium – and are not necessarily a dictator on quality.

Skim milk powder is 8.5% ash, whey powder 11.5% and poorer digested milk proteins, such as whey, permeate at 8.7% ash. An ash content of between 6% to 9% is common.

Calcium, phosphorus and sodium naturally occur in milk powder with quality, low heat-treated ingredients. But if a label shows that any of these have been added, it should be questioned as it is no substitute for those that occur naturally.

While good-quality milk powders are important for calf development, the roles of quality colostrum, transition milk and dry feed should not be discounted.

Calf management in the first few hours of life is integral to ensuring optimal gut development and the long-term performance of the animal, yet understanding how the milk replacer clients are feeding will be digested and used isn’t always clear. If in doubt, seek input from a manufacturer.